The Most Common 3D Printing Problems with Solutions

3D printing is a very fun hobby. However, it does take a lot of trial and error and can give you the odd headache if you’re not sure about what the problem is, especially if you’re a beginner. To help with this, we’ve created a list of the most common 3D printing problems with the solutions to fix them.

Not all problems are hard to fix, as you will see in the solutions. Most problems just need the know-how and the experience to fix it quick. That’s why you should never be put off by potential issues. If all else fails, you can reach out to forums such as 3D Printboard for some helpful and friendly advice or look at our 3D printing support page for useful links.

For now, take a look at some of the most common 3D printing problems that we come across and the solutions to them.

Warping

The base of the printing model will start to lift/bend upwards until it is no longer level with the printing platform. This could also lead to horizontal cracks in the upper parts of the print. This mainly happens because ABS and PLA filament starts to contract very slightly when it cools down, warping happens if the plastic is cooled too quickly.

How to fix this -

1 - The first solution to try is to use a heated print platform and setting the temperature just below the plastics melting point. If you get the temperature spot on, the first layer will stay flat on the printing platform. The printing platform temperature can be set by the slicer software, you should find the recommended temperature for your filament printed on the side of the packaging or on the spool.

2 - The second solution would be to apply glue, this will help keep the base layer stuck to the printing platform and stop it from rising. Applying a small amount of glue evenly on the print bed will increase adhesion and stop it lifting from the edges.

3 - The last solution would be to re-level the printing platform. Incorrect print platform calibration is often one of the main causes of warping. Re-run through the calibration process and check that the bed is fully level and the nozzle height is correct.

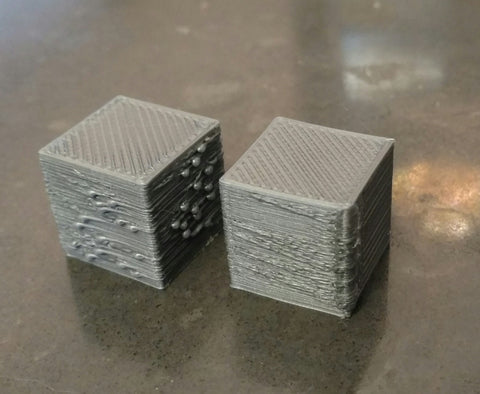

Cracks in prints

Getting cracks in your prints is a common issue. Cracks can often appear on the sides of your prints, especially on taller models. This is definitely one of the most frustrating problems in 3D printing, this is because it tends to mainly effect larger prints and usually whilst you’re not there. In the higher layers, the material cools faster, this is due to the heat from the heated print bed not being able to reach that high. Adhesion will definitely be lower in the upper layers.

How to fix this -

1 - Adjust the extruder temperature. Start by increasing the extruder temperature slightly. We recommend increasing it by around 10ºC and use trial and error. On the side of your filament box you’ll see the working hot end temperatures, try to keep the temperature adjustment within these guidelines.

2 - Check and adjust the fan directions and speeds. Make sure that you double check the fans on your printer to ensure that they’re fully working and aimed directly at the model. If they are facing the model and are fully working, try reducing their speed.

Image used is from Flux Forums

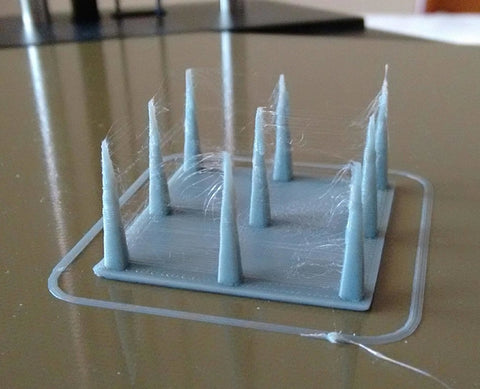

Stringing

Stringing is when 3D prints sometimes have unsightly strings of plastic between parts of the model and where the printer shouldn’t be printing. Stringing happens because the print head moves over an open area and sometimes, filament leaks and drips out of the nozzle leaving a ‘string’ of plastic.

How to fix this

1 - Enabling retraction is key as this helps with the quality of finish and can be enabled through slicing software. The retraction works by retracting the filament back into the nozzle before the head moves. This should avoid molten filament from leaking or dripping as the head moves. On a side note, turning on and using retraction should also increase your print speeds.

2 - If standard retraction isn’t doing the trick, try reducing the minimum travel. This is usually the quickest solution to fix stringing issues. Drop the value by 0.5mm until the stringing has stopped completely.

Image used is from Reddit

Over Extrusion

A common issue in 3D printing is over-extrusion. This means that the printer uses more filament than needed. This results in excess filament on the outside of the printed model but also a lot of wasted filament. The most common cause of this issue is that the extrusion multiplier or flow setting in the slicing software is set too high.

How to fix this

1 - The most common fix is to edit the extrusion multiplier. You can do this by opening your slicer software and checking that the correct extrusion multiplier is selected. This should get rid of the over extrusion issue.

2 - If the extrusion multiplier seems fine and the settings are correct, check the flow setting too. You can try decreasing the flow setting in your printer’s software settings to reduce the risk of over extrusion.

Blocked Nozzle

If you’re trying to start a printing job but nothing is coming out the nozzle, you most likely have a blocked nozzle, especially if you have tried extracting the filament and reinserting it back in doesn’t work.

The most likely cause of a blocked nozzle is due to molten plastic hardening on the end from previous print jobs. It can also be caused by a small amount of filament being left behind after you have changed the spools. This can happen fairly often as the filament could have snapped at the end. When you do load a new filament spool into your printer, that old piece of filament has jammed the nozzle up, not allowing the new filament to travel through.

How to fix this

1 - The most common way to fix this is with a needle. You will need to toggle your printer to heat up the nozzle to the desired temperature (normally 200 degrees for PLA) and use the needle/pin to clear the blockage.

2 - Technology Outlet stocks a special type of cleaning filament that can help unblock blocked nozzles. It comes in a 100g spool so it is good for several uses and it can reduce the risk of blocked nozzles occurring again.

That concludes our list of the most common 3D printing issues and the solutions to them. Leave a comment and let us know if there are any we have missed and we may do a part 2 to this article.

Leave a comment